The Importance Of Selecting The Right Chemical Powder Bag For Your Industrial Needs

In the fast-paced world of industrial manufacturing, the choice of chemical powder bag may seem like a minor decision. However, selecting the right bag can have a significant impact on both the efficiency and safety of your operations. This article delves into the crucial factors to consider when choosing a chemical powder bag for your specific industrial needs, highlighting the importance of this seemingly small detail in the overall success of your operations. Read on to discover how making the right choice can make a big difference.

- Factors to Consider When Choosing a Chemical Powder Bag

When it comes to selecting the right chemical powder bag for your industrial needs, there are several factors that need to be taken into consideration. Choosing the wrong bag can lead to potential hazards, inefficiencies, and even costly consequences. To ensure that you make the best decision for your specific requirements, it is essential to understand the key factors that play a crucial role in the selection process.

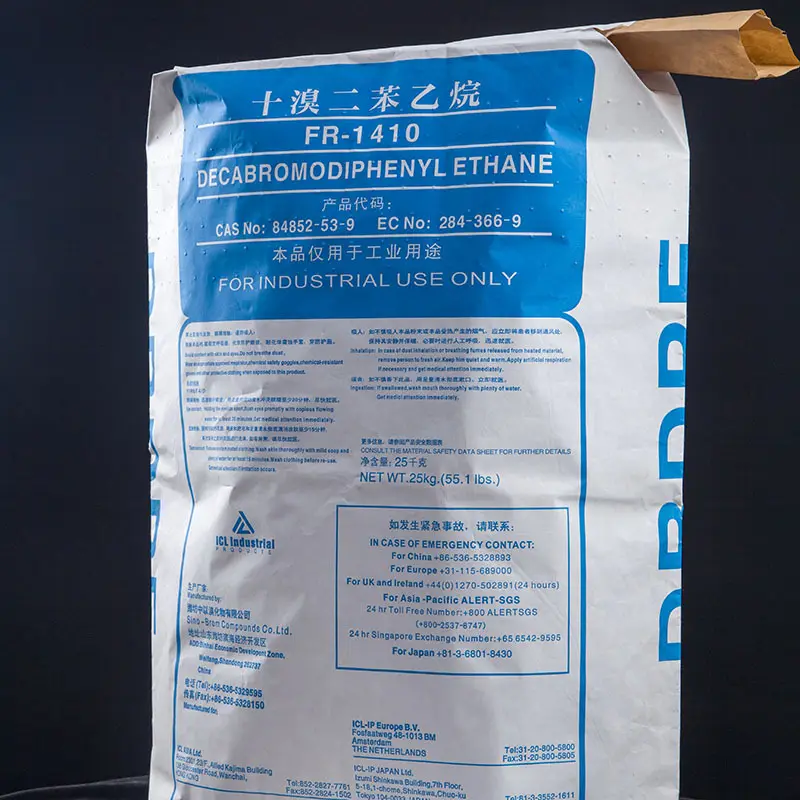

One of the most important factors to consider when choosing a chemical powder bag is the material of the bag itself. The material must be able to withstand the corrosive nature of the chemicals it will be containing. It should also be durable enough to prevent any leaks or spills that could potentially harm workers or damage the surrounding environment. Some common materials used for chemical powder bags include polypropylene, polyethylene, and woven polypropylene.

Another important consideration is the size and capacity of the bag. It is crucial to choose a bag that is the right size for the amount of chemical powder that needs to be stored or transported. Overloading a bag can lead to tears or ruptures, while using a bag that is too large can result in wasted space and inefficiencies. It is important to carefully calculate the required capacity to ensure optimal performance.

The type of closure mechanism is another factor that should not be overlooked when selecting a chemical powder bag. A secure closure is essential to prevent any accidental spills or leaks during transportation or storage. Common closure mechanisms include zippers, heat-sealed tops, and self-sealing tapes. It is important to choose a closure that is reliable and easy to use to ensure the safe containment of the chemical powder.

Additionally, the design of the bag plays a significant role in its functionality. Some bags are specifically designed for easy stacking, while others may have features such as handles or spouts for convenient handling and pouring. Consider the specific requirements of your industrial processes when selecting a bag design to ensure maximum efficiency and safety.

Finally, it is important to consider the cost of the chemical powder bag. While it may be tempting to opt for the cheapest option available, it is essential to prioritize quality and durability over price. Choosing a high-quality bag may initially cost more, but it can save money in the long run by preventing costly accidents or damage.

In conclusion, selecting the right chemical powder bag for your industrial needs is a decision that should not be taken lightly. By carefully considering factors such as material, size, closure mechanism, design, and cost, you can ensure that you choose a bag that meets your specific requirements and provides optimal performance and safety. Make the investment in a high-quality chemical powder bag to protect your workers, the environment, and your bottom line.

- The Impact of Using the Wrong Chemical Powder Bag

In the industrial world, the selection of the right chemical powder bag is crucial to ensure the efficiency and safety of operations. The impact of using the wrong chemical powder bag can be devastating, leading to serious consequences such as contamination, loss of product, and even potential harm to workers and the environment.

Choosing the correct chemical powder bag is essential to prevent any mishaps that may result from using the wrong type of bag. Different chemical substances require specific types of bags to ensure that they are stored and transported safely. The wrong chemical powder bag can lead to chemical reactions, leakage, or even explosions, putting everyone in the vicinity at risk.

One of the most common mistakes in selecting a chemical powder bag is overlooking the compatibility of the bag material with the chemicals it will be in contact with. Some chemicals may react with certain bag materials, causing degradation of the bag and leakage of the contents. This can result in contamination of other products, damage to equipment, and exposure of workers to hazardous chemicals.

Another factor to consider when choosing a chemical powder bag is the strength and durability of the bag. Using a bag that is not strong enough to hold the weight of the chemical powder can lead to ruptures and spills, creating a safety hazard and causing a loss of product. It is important to select a bag with the appropriate strength and thickness to withstand the pressure and weight of the chemical powder it will contain.

Furthermore, the design and construction of the chemical powder bag are also crucial factors to consider. A poorly constructed bag with weak seams or inadequate closure mechanisms can lead to leaks and spills, resulting in a messy and dangerous work environment. It is essential to choose a bag that is well-designed and sturdy to prevent any accidents or incidents.

In addition to safety concerns, using the wrong chemical powder bag can also have financial implications for a company. Loss of product due to spillage or contamination can result in significant financial losses, as well as damage to the company's reputation. Investing in the right chemical powder bag may require a higher upfront cost, but it can ultimately save money in the long run by preventing costly incidents and ensuring the safe and efficient storage and transportation of chemicals.

In conclusion, the impact of using the wrong chemical powder bag cannot be underestimated. It is essential for industrial companies to carefully consider the type of bag they use to store and transport chemicals, taking into account factors such as compatibility, strength, durability, and design. By selecting the right chemical powder bag, companies can ensure the safety of their workers, protect the environment, and avoid costly incidents that may arise from using the wrong bag.

- How to Determine Your Industrial Needs for Chemical Powder Bags

When it comes to industrial operations that involve handling chemical powders, selecting the right type of chemical powder bag is crucial. These bags not only play a key role in the safe storage and transportation of chemical powders but also impact the overall efficiency and effectiveness of the industrial process. In order to determine the right chemical powder bag for your specific industrial needs, it is important to consider a number of factors.

One of the first things to consider when selecting a chemical powder bag is the type of chemical powder being stored or transported. Different types of chemical powders have varying characteristics, including their level of reactivity, moisture sensitivity, and particle size. Some chemical powders may be corrosive, flammable, or toxic, which require specialized bags designed to handle these specific properties. It is essential to match the characteristics of the chemical powder with the appropriate bag to ensure safety and compliance with regulations.

Another important factor to consider is the environment in which the chemical powder bags will be used. Factors such as temperature, humidity, and exposure to sunlight can all impact the durability and performance of the bags. For example, chemical powder bags used in outdoor environments may need to be UV resistant and waterproof, while bags used in high-temperature environments may require heat-resistant materials. Assessing the specific conditions of the industrial setting will help determine the most suitable type of chemical powder bag.

In addition to considering the characteristics of the chemical powder and the environment, it is also important to assess the size and weight of the bags needed for the intended application. Chemical powder bags come in a variety of sizes and weight capacities, ranging from small pouches to large bulk bags. Understanding the volume of chemical powder being handled and the logistics of transportation and storage will help determine the appropriate size and weight of the bags required.

Furthermore, the handling and transportation requirements of the chemical powder bags should also be taken into consideration. Some industrial processes may involve frequent loading and unloading of bags, while others may require bags to be stacked or palletized. In such cases, selecting bags with features such as reinforced handles, bottom spouts, or UV stabilizers can enhance the ease of handling and transportation, ultimately improving operational efficiency and reducing the risk of damage or spillage.

In conclusion, selecting the right chemical powder bag for your industrial needs is a critical decision that can impact the safety, efficiency, and effectiveness of your operations. By considering factors such as the type of chemical powder, environmental conditions, size and weight requirements, and handling and transportation considerations, you can ensure that you choose a bag that meets your specific requirements. Investing time and effort in determining your industrial needs for chemical powder bags will not only help safeguard your employees and the environment but also optimize your overall industrial processes.

- Benefits of Selecting the Right Chemical Powder Bag

When it comes to transporting and storing chemical powders in an industrial setting, selecting the right chemical powder bag is crucial. The type of bag you choose can have a significant impact on the efficiency, safety, and overall success of your operations. In this article, we will explore the benefits of selecting the right chemical powder bag for your industrial needs.

One of the key benefits of choosing the right chemical powder bag is ensuring the safety of your workers and the integrity of your products. Chemical powders can be hazardous materials, and improper storage or handling can result in accidents or contamination. By selecting a high-quality, durable bag that is specifically designed for chemical powders, you can help prevent leaks, spills, and other potential hazards. This not only protects your workers, but also helps to maintain the purity and effectiveness of your products.

In addition to safety, selecting the right chemical powder bag can also improve the efficiency of your operations. A well-designed bag will be easy to handle, transport, and store, making it easier for your workers to move and use the chemical powders as needed. This can help to streamline your processes, reduce downtime, and improve overall productivity. By choosing a bag that is the right size and shape for your specific needs, you can also optimize space utilization and ensure that your chemical powders are stored in the most efficient manner possible.

Furthermore, selecting the right chemical powder bag can also help to extend the shelf life of your products. Chemical powders are often sensitive to moisture, air, and other environmental factors that can affect their stability and effectiveness. A high-quality bag that provides a barrier against these elements can help to protect your products and ensure that they remain viable for as long as possible. By choosing a bag that is designed to preserve the quality of your chemical powders, you can reduce waste, improve product consistency, and ultimately save money in the long run.

When selecting a chemical powder bag for your industrial needs, there are several factors to consider. First and foremost, you should ensure that the bag is made from a material that is compatible with the specific type of chemical powder you will be storing. Different materials have different properties, such as resistance to moisture, chemicals, and abrasion, so it is important to choose a bag that meets your requirements. Additionally, you should consider the size, shape, and closure mechanism of the bag to ensure that it is practical and convenient for your operations.

In conclusion, selecting the right chemical powder bag is essential for ensuring the safety, efficiency, and effectiveness of your industrial operations. By choosing a high-quality bag that is designed for the specific needs of chemical powders, you can protect your workers, improve productivity, and extend the shelf life of your products. Investing in the right bag may require some upfront costs, but the long-term benefits far outweigh the initial expense. Take the time to carefully assess your needs and select a bag that will provide the best possible solution for your chemical powder storage and transportation requirements.

- Tips for Properly Storing and Handling Chemical Powder Bags

Chemical powder bags play a crucial role in various industries, including pharmaceuticals, food processing, and agriculture. They are used to store and transport a wide range of chemical powders, such as fertilizers, pesticides, and pharmaceutical ingredients. Properly selecting the right chemical powder bag is essential to ensure the safety and effectiveness of these valuable materials. However, it is equally important to know how to properly store and handle these bags to avoid any accidents or contamination.

When selecting a chemical powder bag, there are several factors to consider. The material of the bag is one of the most important aspects to take into account. Different chemicals may interact with certain materials, so it is essential to choose a bag that is compatible with the specific chemical being stored. For example, some chemicals may require a bag with a barrier coating to prevent moisture infiltration or to protect against UV exposure.

Another factor to consider is the size and weight capacity of the bag. It is crucial to ensure that the bag can comfortably hold the amount of chemical powder being stored without putting strain on the material. Overfilling a bag can lead to tears or leaks, potentially causing spills and accidents.

Additionally, the design of the bag should be considered. Some chemical powders may require a bag with a specific closure mechanism, such as a zip lock or heat seal, to prevent any leakage or contamination. The bag should also be durable enough to withstand handling and transportation without tearing or breaking.

Once the right chemical powder bag has been selected, proper storage and handling are essential to maintain the integrity of the material. Chemical powders should be stored in a cool, dry place away from direct sunlight and moisture. They should also be kept in a dedicated storage area away from other materials to prevent cross-contamination.

When handling chemical powder bags, it is important to follow safety guidelines and precautions. Employees should wear appropriate protective gear, such as gloves and goggles, when handling chemical powders to prevent any skin or eye contact. Bags should be handled with care to avoid any tearing or puncturing that could lead to spills or leaks.

In conclusion, selecting the right chemical powder bag for your industrial needs is crucial for ensuring the safety and effectiveness of the materials being stored. By considering factors such as material compatibility, size, weight capacity, and design, you can make an informed decision on the best bag for your specific application. Proper storage and handling practices are equally important in maintaining the integrity of the chemical powders and preventing any accidents or contamination. By following these tips, you can safely and efficiently store and handle chemical powder bags in your industrial setting.

Conclusion

In conclusion, selecting the right chemical powder bag for your industrial needs is paramount in ensuring the safety, efficiency, and success of your operations. With our 13 years of experience in the industry, we understand the importance of choosing the right packaging solution for your specific requirements. From ensuring proper containment and protection of your chemical powders to improving handling and transportation efficiencies, the right bag can make a significant difference in your overall operations. Trust in our expertise and experience to help you select the perfect chemical powder bag for your industrial needs.