The Ultimate Guide To Chemical Powder Packaging Bags: Everything You Need To Know

Are you looking for information on chemical powder packaging bags? Look no further! In our comprehensive guide, we cover everything you need to know about these essential packaging solutions. From different types of bags to tips on proper handling and storage, we've got you covered. Keep reading to learn all about the ultimate guide to chemical powder packaging bags.

- Types of Chemical Powder Packaging Bags

Chemical powder packaging bags are essential for industries that deal with the storage and transportation of various types of chemical powders. These bags are designed to ensure the safe containment of the powders while also providing ease of handling and transport. There are several types of chemical powder packaging bags available in the market, each with its own unique features and benefits. In this article, we will explore the different types of chemical powder packaging bags to help you choose the best option for your specific needs.

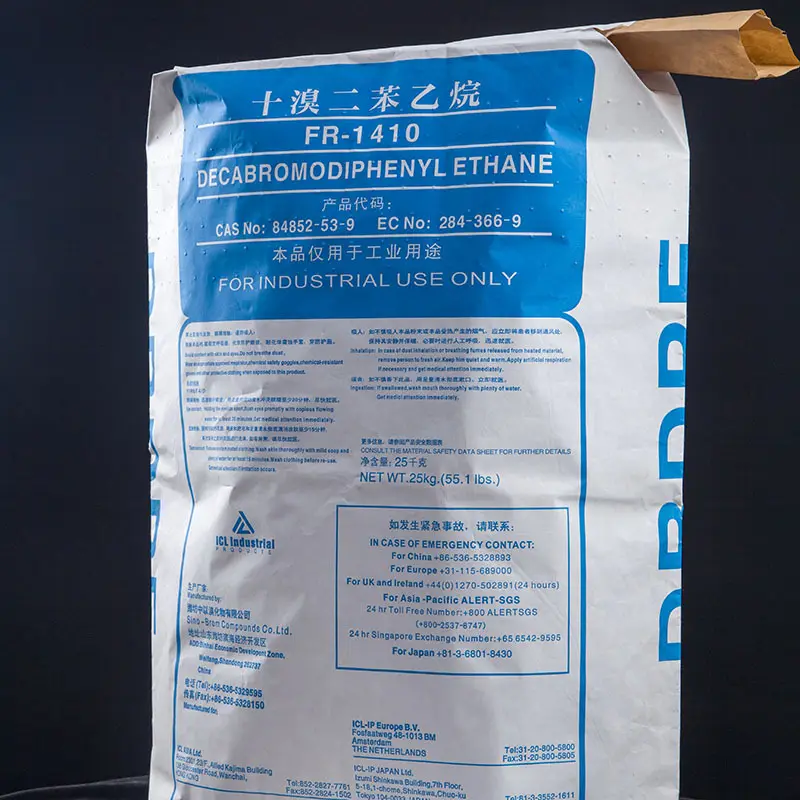

1. Paper Bags:

Paper bags are one of the most common types of chemical powder packaging bags. They are made from kraft paper, which is a strong and durable material that can withstand the weight and pressure of the chemical powders. Paper bags are lightweight and eco-friendly, making them a popular choice for packaging various types of chemical powders. They are also easily recyclable, which adds to their sustainability.

2. Polyethylene Bags:

Polyethylene bags are another popular option for chemical powder packaging. These bags are made from a durable plastic material that is resistant to punctures and tears. Polyethylene bags are also waterproof, providing an added layer of protection to the chemical powders stored inside. These bags are available in various thicknesses, making it easy to choose the right option based on the specific needs of the chemicals being packaged.

3. FIBC Bags:

Flexible Intermediate Bulk Containers (FIBC) bags, also known as bulk bags, are a larger type of chemical powder packaging bag. These bags are made from woven polypropylene fabric and are designed to hold a significant amount of chemical powder. FIBC bags come in various sizes and designs, including options with different types of closures and lifting mechanisms for easy handling and transport.

4. Valve Bags:

Valve bags are a specialized type of chemical powder packaging bag that includes a valve or spout for easy filling and dispensing of the powders. These bags are typically made from multi-layer materials such as paper, plastic, and aluminum, providing an extra barrier against moisture and air. Valve bags are commonly used for packaging fine and dusty chemical powders that require extra protection during storage and transportation.

5. Form-Fill-Seal Bags:

Form-fill-seal bags are a convenient and efficient option for chemical powder packaging. These bags are made from a single roll of film that is formed, filled with the chemical powder, and sealed in one continuous process. Form-fill-seal bags are customizable in terms of size, shape, and material, making them suitable for various types of chemical powders. These bags are also tamper-evident, ensuring the safety and integrity of the powders inside.

In conclusion, choosing the right type of chemical powder packaging bag is essential to ensure the safe and efficient storage and transportation of chemical powders. Each type of packaging bag offers unique features and benefits, so it is important to consider your specific needs and requirements before making a decision. Whether you opt for paper bags, polyethylene bags, FIBC bags, valve bags, or form-fill-seal bags, knowing the characteristics of each type will help you make an informed choice for your chemical powder packaging needs.

- Factors to Consider When Choosing Packaging Bags for Chemical Powders

Chemical powder packaging bags are an essential component in the safe and efficient transportation and storage of various chemical powders. When choosing the right packaging bag for your chemical powders, there are several factors that need to be considered to ensure the integrity of the product and the safety of those handling it. In this comprehensive guide, we will delve into everything you need to know about chemical powder packaging bags and the key factors to consider when selecting the best option for your specific needs.

1. Material:

The first and most crucial factor to consider when choosing packaging bags for chemical powders is the material they are made of. The material of the bag should be able to withstand the corrosive nature of the chemicals it will be containing. Common materials used for chemical powder packaging bags include polyethylene, polypropylene, and foil laminates. Each material has its own strengths and weaknesses, so it's essential to choose a material that is compatible with the specific chemical powder being packaged.

2. Barrier Properties:

Another important factor to consider is the barrier properties of the packaging bag. The bag should be able to effectively prevent moisture, oxygen, light, and other contaminants from penetrating the bag and affecting the quality of the chemical powder. Look for packaging bags that offer high barrier properties to ensure the longevity and integrity of the product.

3. Strength and Durability:

Chemical powders can be heavy and abrasive, so it's crucial to choose packaging bags that are strong and durable enough to withstand the weight and pressure of the product. Consider the thickness and strength of the bag material, as well as the construction of the bag (e.g., sewn, heat sealed) to ensure that it can safely contain the chemical powder without rupturing or tearing.

4. Compatibility:

When selecting packaging bags for chemical powders, it is essential to consider the compatibility of the bag with the specific chemical being packaged. Some chemicals may react with certain bag materials, leading to contamination or degradation of the product. Make sure to choose packaging bags that are chemically resistant and compatible with the chemical powder to avoid any potential hazards.

5. Safety and Regulations:

Safety should always be a top priority when dealing with chemical powders. Ensure that the packaging bags you choose meet all safety regulations and standards for handling and transporting hazardous materials. Look for bags that are labeled as compliant with regulatory standards such as UN, FDA, and DOT to ensure that they meet the necessary safety requirements.

In conclusion, selecting the right packaging bags for chemical powders is a critical decision that can impact the safety, quality, and integrity of the product. By considering factors such as material, barrier properties, strength and durability, compatibility, and safety regulations, you can choose the best packaging bags to meet your specific needs and ensure the safe and secure transportation and storage of chemical powders. Remember to carefully evaluate these factors and choose a packaging bag that is tailored to the unique requirements of the chemical powder being packaged.

- Benefits of Using Properly Designed Packaging Bags for Chemical Powders

Chemical powder packaging bags play a crucial role in ensuring the safety, efficiency, and effectiveness of storing and transporting various chemical powders. When it comes to handling hazardous substances such as chemical powders, it is vital to use properly designed packaging bags that are specifically tailored to meet the unique requirements of these materials. In this comprehensive guide, we will explore the benefits of using properly designed packaging bags for chemical powders.

One of the primary advantages of using properly designed packaging bags for chemical powders is enhanced safety. Chemical powders can be extremely volatile and reactive substances that require specialized packaging to prevent spills, leaks, or contamination. Properly designed packaging bags are made from durable materials that are resistant to punctures, tears, and other forms of damage, providing an extra layer of protection against potential hazards.

In addition to safety concerns, properly designed packaging bags also help to maintain the integrity and purity of the chemical powders they contain. These bags are often constructed using barrier materials that provide a high level of protection against moisture, oxygen, light, and other external factors that can degrade the quality of the powders. By using packaging bags that are specifically engineered to prevent degradation, chemical powders can retain their effectiveness and stability for longer periods of time.

Furthermore, properly designed packaging bags for chemical powders are also designed with convenience and ease of use in mind. These bags are often equipped with features such as resealable closures, easy-to-read labels, and ergonomic handles for effortless handling and storage. This not only contributes to a more efficient and organized workflow but also reduces the risk of spills, accidents, and injuries in the workplace.

In conclusion, the benefits of using properly designed packaging bags for chemical powders cannot be understated. These bags provide a vital layer of protection against potential hazards, help to maintain the integrity and purity of the powders, and offer convenience and ease of use for handling and storage. By investing in high-quality packaging bags that are tailored to the unique requirements of chemical powders, businesses can ensure the safety, efficiency, and effectiveness of their operations. Remember, when it comes to storing and transporting hazardous substances like chemical powders, proper packaging is key.

- Tips for Properly Sealing and Storing Chemical Powder Packaging Bags

Chemical powder packaging bags play a crucial role in the safe storage and transportation of various types of chemical powders. With proper sealing and storage techniques, you can ensure the integrity of the product and prevent any leaks or spills. In this comprehensive guide, we will explore the best practices for sealing and storing chemical powder packaging bags.

Sealing chemical powder packaging bags is a critical step in ensuring the safety and quality of the contents. Proper sealing not only prevents the powder from spilling out but also helps to protect it from moisture and other contaminants. When sealing the bags, it is important to ensure that the closure is secure and airtight. This can be achieved by using heat sealers or other sealing methods that are specifically designed for chemical powders.

It is also important to properly label the bags with the name of the product, batch number, and any other relevant information. This will help to quickly identify the contents of the bag and prevent any mix-ups or confusion. Additionally, storing the bags in a cool, dry place away from direct sunlight and extreme temperatures is essential to maintain the integrity of the contents.

When storing chemical powder packaging bags, it is important to keep them away from sources of heat or open flames. Chemical powders can be flammable and storing them near heat sources can pose a fire hazard. Additionally, it is important to store the bags away from any direct sunlight, as UV rays can degrade the packaging material and affect the quality of the contents.

To further ensure the safety of the chemical powders, it is recommended to store the bags in a secure location that is out of reach of children and pets. Chemical powders can be harmful if ingested or inhaled, so it is important to take precautions to prevent accidental exposure.

In conclusion, proper sealing and storing of chemical powder packaging bags are essential to ensure the safety and quality of the contents. By following the tips outlined in this guide, you can effectively protect the chemical powders from spills, contamination, and other hazards. Remember to always handle chemical powders with care and follow the manufacturer's guidelines for storage and handling. With the right practices in place, you can confidently store and transport chemical powders in a safe and secure manner.

- Common Mistakes to Avoid When Packaging Chemical Powders

When it comes to packaging chemical powders, there are several common mistakes that must be avoided in order to ensure the safety and effectiveness of the product. In this ultimate guide to chemical powder packaging bags, we will delve into everything you need to know in order to successfully package and transport your chemical powders.

One of the most important factors to consider when choosing packaging bags for chemical powders is the material. It is essential to select bags that are made from high-quality materials that are durable and can withstand the harsh conditions that chemical powders may present. Some common materials used for chemical powder packaging bags include polyethylene, polypropylene, and nylon. These materials are known for their strength and resistance to chemicals, making them ideal for packaging chemical powders.

Another important aspect to consider when packaging chemical powders is the design of the bag. It is crucial to choose a design that is suitable for the type of chemical powder being packaged. For example, if you are packaging a fine powder that is prone to leaking, it is important to choose a bag with a tight seal to prevent any spillage. Additionally, it is important to consider the size and shape of the bag to ensure that it can hold an adequate amount of powder without becoming too bulky or difficult to handle.

In addition to material and design, it is also important to consider the labeling of chemical powder packaging bags. Proper labeling is essential for ensuring the safe handling and transport of chemical powders. Labels should include important information such as the name of the chemical powder, any hazards associated with it, and proper handling instructions. This information is crucial for ensuring that the product is handled safely and correctly.

One common mistake to avoid when packaging chemical powders is using bags that are not designed for the specific type of powder being packaged. Using the wrong type of bag can lead to leaks, spills, and contamination, which can pose serious risks to both the product and those handling it. It is important to carefully consider the properties of the chemical powder and choose a bag that is specifically designed to handle it.

Another common mistake to avoid is using inadequate sealing methods. Proper sealing is essential for preventing leaks and contamination of chemical powders. It is important to use sealing methods such as heat sealing or zip locks to ensure that the bag is tightly sealed and secure. Inadequate sealing can lead to leaks, spills, and exposure to the chemical powder, which can be dangerous and pose serious health risks.

In conclusion, packaging chemical powders requires careful consideration of the materials, design, labeling, and sealing methods used for the packaging bags. By avoiding common mistakes such as using the wrong type of bag or inadequate sealing methods, you can ensure that your chemical powders are safely and effectively packaged for transport and use. By following the guidelines outlined in this ultimate guide to chemical powder packaging bags, you can ensure the quality and safety of your products.

Conclusion

In conclusion, after delving into "The Ultimate Guide to Chemical Powder Packaging Bags: Everything You Need to Know," it is clear that a thorough understanding of the intricacies involved in packaging chemical powders is essential for any company in the industry. With our 13 years of experience, we have gained valuable insights into the importance of high-quality packaging materials, proper labeling, and adherence to safety regulations. By following the tips and recommendations provided in this guide, businesses can ensure the safe and effective containment of their chemical powders, ultimately leading to increased productivity and customer satisfaction. Trust in our expertise and experience to help you navigate the world of chemical powder packaging with confidence.